TABLE OF

CONTENTS

Table

of contents………………………………………………………..i

SR. NO. CONTENTS Page No. Introduction………………………………………………………...5

1.1 Purpose…………………………………………………………….6

1.2 Problems/Limitation…………………………………………6

1.3 Description of the scheme………………………………….7

1.4 Natural slope available………………………………………7

1.5 Ground water level…………………………………………….7

1.6 Scope…………………………………………………………………8

1.7 Elements of sewerage system……………………………..9.

Design

Criteria……………………………………………………..11

2.1 Sources of waste water………………………………………11

2.2 Sewerage treatment……………………………………..…….11

2.3 Description of sewerage system………………………….12

2.4 Assumptions…………………………………………………...….13

2.4.1 Design

period…………………………….………….13

2.5 Estimation of sewage quantities…………………………..13

2.5.1 Per capita

water consumption……………..…13

2.5.2 Per capita

water consumption for Future

Vision

Housing Society …………………………..14

2.5.3 Average

sewage flow…………………...…………14

2.5.4 Peak sewage

flow………………….………………..14

2.5.5 Infiltration………………….…………………………..15

2.6 Storm flow

capacity of a sewer………………………………15.

2.7 Design flow………………………………….………………………15

2.8 Sewer pipes and connections………………………………..16

2.9 Size of sewer…………………………………………..……………16

2.10

Minimum sewer size…………………………………………16

2.11

Slope of sewer……………….………………………………….17

2.12

Sewer design equation…………………...………………….17

2.13

Velocity of flow………………………………………………….17

2.13..1

Minimum velocity…………………………..……17

2.13..2

Maximum velocity……………………………….18

2.14

Minimum cover of sewer……………………………………18

2.15

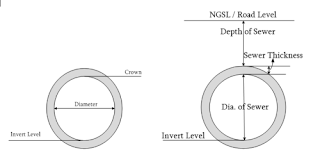

Invert level…………………………………………………………18

2.16

Provision of manhole……..……………………………………20

2.16..1

Manholes………………………………………………21

2.16..2

Drop manholes…………………..………………….21

2.17

Direction of sewer line…………………………………………22

2.18

Inlet……………………………………………...……………………..22

2.19

Catch basin…………………………….…………………………….22

2.20

Maximum depth of sewer……………………………………..22

2.21

Joints in sewer pipe………………………………………………22

2.21..1

Bell and Spigot joints………………………………22

2.21..2

Tongue and Groove joints…………………….….23

2.22

Sewage pumping station……………………………….………23

2.23

Types of bedding………………………………………………….24

2.23..1

Sewer bedding……………………………………….24

Design of

sewerage system………………………………………..27

3.1 Design

procedure…………………………………………………..27

Conclusion…………………………………………………………………30 Reference…………………………………………………………………..31

Annexure …………………………………………………………………..3

CHAPTER1

INTRODUCTION

ENVIRONMENTAL ENGINEERING is a professional engineering

discipline that deals with the design, construction, and maintenance of the

physical and naturally built environment, including works like sewage design,

treatment plants, pumping stations and transmission lines etc. Environmental engineering is the branch of

civil engineering which is the oldest engineering discipline after military

engineering, and it was defined to distinguish non-military engineering from

military engineering.

Water is one of

the most valuable natural resources essential for human and animal life,

industry and agriculture. Wastewater causes more than 50 diseases so as an

environmental engineer it is our duty to save the environment & as well as

the human health which is affected by these diseases. In fact, there is hardly

any human activity which is not in one way or another, affected by water. Sewerage refers to the collection,

treatment and disposal of liquid waste. Sewerage system includes all physical

structures required for the collection, treatment and disposal.

The sewage, once it enters the sewers, becomes the

responsibility of the community. Small communities which have managed in the

past with on-site disposal systems may be well-advised to avoid modernization.

1.1 Purpose

The

purpose of this report is to know the various design components related to

waste water (sewage) design. Wherever high a community is planned to be established,

then waste water treatment becomes a big issue for engineers. So this report

can help us to understand the various sewage design parameters and components

which are to be used to solve various engineering problems and to perform work

in a better way.

1.2 Problems/ Limitations

In every environmental engineering

project, engineers face many problems, sometimes, problems related to

management. Time management is very important during a mega project for an

engineer. Manual working and old construction techniques delay the project

significantly and contractor has to pay for penalty on daily basis. Therefore,

engineers must learn different design software related to environmental

engineering to save the time and to solve the relevant problems in an effective

way.

1.3 Description

of the Scheme

a) Nasheman-E-Iqbal Housing

Society

Future Vision Housing

Society provides an exquisite living experience

that is situated at the shaokat khanum Road. The society is being developed

using state of the art design and incorporating all amenities of modern life.

b) Salient

Features

ü A total of 936 plots, available in

different sizes, suiting all family sizes and requirements.

ü School

ü Commercial Area

ü Disposal Station

ü Grave yard

1.4 Natural slopes

Available

From plan of

Nasheman-E-Iqbal Housing Society, we can see that the topography of this area

is almost same, the average elevation is taken as 252m. .The topography of the

area is flat according to topography of Punjab. So slope is 1 to 2%. &

Sewer must follow the natural slopes.

1.5 Ground water levels

In the given scheme the ground water table

is low. So we will use the brick ballast bedding. Mostly we do dewatering while

making trenches when the ground water table is high. Infiltration also depends

upon ground water table. We go 9m to 10m down.

1.6 Scope

As far as the scope of report is

concerned it has wide range of application in today’s field. As around the

world the idea of sewage and waste water treatment is quickly prevailing as

well as in Pakistan so this report will help in better understanding of

designing a sewage system for a community.

This

report will give the introduction and background of waste water engineering

which are necessary for performing the work at site efficiently. This report

will also provide a simplified explanation of construction method at the site.

Why Sewerage system is

required:

We use water supply system in order to provide easy

availability of water for drinking , washing etc. when this water is used it

becomes waste water called "sewage". Proper system is required for

the collection of waste water and conveying it to the point of disposal with or

without treatment called as

"sewerage.

Most of the paving types are generally

impermeable, i.e. water does not drain through them, but collects on the

surface and therefore all pavements must be designed to drain towards a gully,

a linear drain or some other handy disposal point, such as a ditch or towards

the public footpath/highway.

Failure to properly drain a

pavement can cause all sorts of problems. Water on the surface encourages

mosses, algae and other vegetation to colonize the paving. Accumulation of

water can cause growth of various micro- organisms, flies, mosquito, worms, and

protozoa etc. which are cause of various diseases. These cause over 50 diseases

to human.

So a properly designed system must be provided.

1.7

Elements of Sewerage System

The sewerage system consists of three

elements:

·

Collection

Works

·

Disposal

Works

·

Treatment

Works

CHAPTER 2

DESIGN CRITERIA

What is design?

In engineering sciences design is a term used in special meaning and is

referred to the creation or development of some system or component by

engineered manner. By McGraw-Hill Dictionary of Engineering, designing is

defined as, “A branch of engineering concerned with the creation of systems,

devices, and processes useful for the society.”

2.1

Sources of Waste Water

Following are the principal sources

of waste water

- Industrial

It is the liquid waste from the industrial

places from their different industrial processes like dying, paper matting, tanneries,

chemical industries, etc.

- Storm Water

It

includes surface runoff generated from rainfall and the street wash.

2.2 Sewage

Treatment

Sewage treatment, or domestic wastewater

treatment, is the process of removing contaminant from wastewater, both runoff

and domestic. It includes physical, chemical and biological processes to remove

physical, chemical and biological contaminants. Its objective is to produce a

waste stream (or treated effluent) and a solid waste or sludge also suitable

for discharge or reuse back into the environment. Sewage is treated to control

water pollution before discharge to surface waters.

The purpose of is the preservation of

health of the individual and the community, by preventing the communicable

diseases.

2.3 Description of Sewerage System

There are three types of

sewer system which are given below:-

Separate system

Combined system

Partially Combined system

Separate System:-

If storm water is carried separately

from domestic and industrial waste waters, the system is called separate

system. Separate systems are preferred when

- There is an immediate need for collection of sanitary sewage but not for storm water.

- When sanitary sewage needs treatment and storm water does not.

Combined System:-

It is the system in which the sewers carry

both sanitary and storm water. Combined systems are preferred when:

- Combined sewage can be disposed off without treatment

- Both sanitary and storm water need treatment

- Streets are narrow and two separate systems can’t be laid.

Partially Combined System:-

If some portion of storm or surface runoff is allowed to be

carried along with sanitary sewage, the system is known as partially combined

system.

Note: In urban areas of developing

countries, mostly partially combined system is employed as it is economical.

We have designed system as “Partially Combined System “which is

most suitable for developing countries like Pakistan.

2.4

Assumptions

2.4.1 Design Period:

Period of design is indefinite. The system is designed to

take care for the maximum development of the area. But here Design period of

our sewer system is 20 years.

Relation

of sewage Generation with Water Consumption

Around

80 to 130 % of water consumed gets into sewers.130 % sewage flow is obtained

when

v Industries having private sources of water discharge their

effluent into municipal sewer.

v When sewer joints are poor and it is laid below water table

then infiltration occurs

General range is 80 to 90 % of water consumption.

v When infiltration is taken into account then; avg rate of

sewage flow equals the average rate of water consumption i.e. 100%.

2.5

Estimation of Sewage Quantities

2.5.1 Per capita water

consumption:

It is the amount of water consumed by every

individual in a community in a day. It is usual to express water consumption in

liters per capita per day, lpcd

The amount of sewage produced from this water consumed will

be termed as per capital sewage flow. In our case we have calculated this per

capita sewage flow by taking 80% of per capita water consumption.

2.5.2 Per Capita Water Consumption for Nasheman-e-Iqbal

Housing Society

Average Per capita sewage

generationS =( 300+ sum of last two

digits of Regd. No)

=

300 + (0+7) = 307lpcd

2.5.3 Average Sewage Flow

For the present design which has

to be suggested us to use 80 % of water consumption for sewage.

2.5.4 Peak Sewage Flow

HERMAN’S FORMULA:

Like

water supply, sewage flow varies from time to time. Since sewers must be able

to accommodate Maximum Rate of Flow, the variation in the sewage flow must be

studied.

Generally

Herman’sFormula is used to estimate the ratio of Maximum to Average Flow.

P

is population in thousand

Peak sewage flow is calculated by multiplying the average

daily sewage flow by a certain factor. The factor depends on the average flow

and is given by this table.

2.5.5

Infiltration

It is amount of

water that enters into the sewers through poor joints, cracked pipes, walls and

covers of manholes.

It is nonexistent during dry weather but increases during rainy

season.

WASA

Lahore has specified following infiltration rates for design of sewer system;

Sewer

Diameter

|

Infiltration

|

225 mm to 600 mm

|

5 % of Avg. Sewage Flow

|

> 600 mm

|

10 % of Avg. Sewage Flow

|

2.6 Storm Flow Capacity of

Sewer

In the present design

the storm water flow capacity of sewer is taken as equal to peak flow.

Storm

Water Flow = Peak Flow (Qmax)

2.7 Design Flow

First of all calculate the average

sewage flow on the basis of water consumption and the population at the end of

the design period. I.e. at the full development of the area. Then the design

flow for sanitary sewer and partially combined sewers can by calculated by

using the following formulae;

For partially combined sewer: Designs = 2xPeak sewage flow +

infiltration + industrial flow

So,

Qdesign

= Qmax + 10% of infiltration + Qmax

2.8 Sewer Pipes and Connections

Different types of pipes

that are used in the sewer system are

·

PCC pipes (100mm-600mm diameter)

·

RCC pipes (225mm-4500mm diameter)

·

PVC pipes

·

AC pipes

·

C.I pipes

·

Clay

PVC and AC are employed by

households.

PCC and RCC are most widely

used in cities.

CI and Steel are used under

unusual loading conditions and in force mains.

Clay pipes were used in the

past as sewers.

We are using RCC pipes in

our system.

2.9 Size of Sewer

Use the following

relation to find the diameter of sewer

Qf = A x V

2.10 Minimum Sewer Size

225mm is taken as the minimum sewer

size. The reason being that, the choking does not take place even with the

bigger size particles, which are usually thrown into the sewer through

manholes.

2.11 Slope of Sewer

Select the minimum

velocity value and use the Manning’s formula

2.12 Sewer

Design Equation

Manning’s Equation is used for sewers

flowing under gravity

Where

V= Velocity of flow in m/sec

R= Hydraulic mean depth (A/P) = D/4 when pipe is flowing full or half full

S= Slope of the sewer

n= Coefficient of roughness for pipes

(different value for different type of materials)

2.13 VELOCITY OF FLOW

2.13.1

Minimum (Self Cleansing) Velocity

Sewage should

flow at all times with sufficient velocity to prevent the settlement of solid

matter in the sewer. Self-cleansing Velocity is the minimum velocity that

ensures non settlement of suspended matter in the sewer.

The following minimum velocities are generally employed.

- Sanitary sewer = 0.6 m/sec

- Storm sewer = 1.0 m/sec

- Partially combined sewer = 0.7 m/sec

As our design is partially combined system so

minimum velocity is 0.7 m/s.

2.14 Minimum Cover of Sewer

1m is taken as the minimum cover over

the sewers to avoid damage from live loads coming on the sewer.

2.15 Invert level (I.L)

The lowest inside

level at any cross-section of a sewer pipe is known as Invert Level at that

Cross-section.

Invert Level = NGSL/Road Level – Depth of Sewer – Thickness of Sewer – Dia. of Sewer

The

main significance of the invert level is that sewers must be designed and laid

at a specific slope to attain self -cleansing velocities. The required slope is

achieved through calculations of this invert level of the sewers at various

manholes.

Calculation of I.L

For single pipe:

§ Upstream Invert level = NGSL – Depth of sewer – Thickness of sewer –

Diameter of the sewer

§ Downstream invert level = Upstream

invert level – (Length* Slope)

Fall:

Fall is calculated by multiplying the length of the sewer by

the slope of the same particular sewer. This fall is necessary for the

calculation of the invert level at the downstream level.

Fall= Slope of sewer x Length of the sewer.

2.16 Provision of Manhole

2.16.1 Manholes:-

A manhole (alternatively utility hole, maintenance hole,

inspection chamber or access chamber) is the top opening to an underground

utility vault used to house an access point for making connections or

performing maintenance.

Purpose

of providing manhole is

- Cleaning

- Inspection

- House connection

Manholes are provided at:

- Change in sewer direction

- Where diameter of sewer changes

- Where slope of sewer changes

- It is also provided at junctions.

- One man hole for two plots

Spacing of Manhole: (WASA Criteria)

o For

pipe 225mm to 380mm

spacing = 100m

o For

pipe 460mm to 760mm

spacing = 120m

2.17 Direction of Sewer

Line

Sewers should follow as for as

possible, the natural slope so that sewage can flow easily under gravity and

minimum excavation is required which is essential for economizing the system.

2.18 Inlets

An inlet is an opening into a storm or combined sewer for entrance of

storm runoff. It is designed to permit the passage of water from the street

surface into the sewer.

Two types of inlets are

recommended for the system

a)

Curb Inlet

b) Gutter Inlet

2.19 Catch Basin

These are like inlets but

deeper enough to store the settled grit which is then removed periodically.

2.20 Maximum Depth of Sewer

The maximum

depth for sewer suggested for this area is 6-7 m

2.21 Joints in Sewer

Pipe

2.21.1Bell

and Spigot Joints

Employed for sewer

from 225mm to 760mmФ

2.21.2

Tongue and Groove Joints

Employed for sizes

> 760mmФ

We

selected ball and Spigot Joints for our design.

2.22 Sewage Pumping Station

To elevate and transport waste water when

- Continuation of gravity flow is no longer feasible.

- Basements are deep.

- Any obstacle lies in the path of sewer.

- Receiving stream is higher than the sewer.

- Sewage is to be delivered to an above ground treatment plant.

2.23

Type of Bedding

2.23.1 Sewer Bedding

If sewer is simply

laid by placing the pipe on flat trench bottom, the pipe will not be able to

support the load significantly greater than the “Three Edge Bearing test”.

However if bedding touches at least lower quadrant of sewer and backfill

material is carefully tempted, the supporting strength of pipe significantly

increases. Load factor represent this increase in strength,

Load Factor = Load Carrying Capacity/ 3-Edge

bearing strength

Sewer Bedding (Recommended By WASA):-

Three types of sewer bedding

are recommended by WASA.

(These will be used depending upon site

conditions and requirements.)

1) Brick Ballast:-

This type of bedding is used

under poor subsoil conditions, above water

table.

§ Size of the ballast

: 1-1.5 inch gauge (Broken from first class bricks)

§ Load Factor

: 1.7

2) Crushed Stone:-

It is used under poor subsoil

conditions below the water table

§ Size of the ballast

: 0.75-1.5 inch gauge

§ Load Factor

: 1.9

3)

Concrete cradle:-

It is used under increased strength

requirements.

Load

Factor : 3.0

Chapter 3

DESIGN OF SEWERAGE SYSTEM

PROCEDURE

3.1 Design Procedure

Following procedure is adopted for

design:

1) First of all we draw the layout of sewer system keeping in

view the layout of roads and streets so as to avoid overlapping of water

supply, gas and sewer pipes.

2) Represented the sewer with a line and manhole by a dot.

2)

3) Numbered the manholes and identified each sewer line.

3)

4) Then measured the length of each sewer line as per scale of

the map.

4)

5) Adopted per capita sewage flow as 80% of water consumption.

5)

6) Calculated avg. sewage flow and Infiltration for each sewer

line.(using WASA criteria)

7) Found out the peak factor for our project using WASA

criteria. For peak factor first found out the avg. sewage flow for design

population and on the basis of flow we decided the approximate peak factor from

table of peak.

8) Calculated the peak flow and finally the design flow for

sewer lines. As our system is partially combine so I have added storm flow

equal to the peak flow for design flow determination (as per WASA criteria.)

8)

9) Using method of calculation, found approximate dia and slope

for the sewer line assuming that sewer is flowing full. For back calculation I

have chosen velocity equal to 0.7 m/sec for partially combined system.(WASA Criteria)

9)

10) In the end I found out the invert levels for each sewer and

filled the

Table of calculations called “Hydraulic Statement”.

11) Draw the profiles or longitudinal-sections for sewer line

Comments

Following are the different criteria’s

that I consider while designing the sewer system

- We designed for the partially combined sewage system considering economics.

- The design flows are based on the WASA standards.

- Minimum velocity is taken as 0.7 m/sec

- Velocity must not be more than 2.4 m/sec.

- Minimum diameter is taken as 225 mm and other diameters are considered according to WASA standard.

- Minimum rate of sewage flow is taken as 50% of average sewage flow.

- Minimum clear cover of 1-m is provided above the sewer in order to avoid from impact of live loading.

CHAPTER 4

CONCLUSION

The job assigned to me by Authority, was to design the water

sewerage system for Nasheman-E-Iqbal Housing Society. The scheme has 936 residential

plots, school, commercial areas and disposal station.

I have tried to make design as much

economical as possible without compromising on safety of the system. Design is

economical because I have used RCC pipes as sewers. They possess high strength

and durability. Therefore they have longer life which ultimately makes them

suitable and economical. The strength of the system is built-in. Lower

installation cost combines with the other benefits of reinforced concrete pipe

to yield a superior drainage system. I have followed as much as possible the

natural slope. Due to those reason excavation is minimum. It also helps to

economize the system. Wherever lateral or sub main joins in a deeper sewer

excavation is also saved by providing drop manholes by keeping upper sewer at a

reasonable grade. I

have done this whole design work with the best use of my knowledge and skills

in the context of the information provided to me by my teachers. In the whole

design I have made possible that every step should be clear so that the checker

or the reader of the report could not found any difficulty in it.

I am sure to say that system has been designed with great

care and all possible circumstances have considered. Therefore I am very

confident saying that system will be working very well throughout its design

period of 20 years which is from 2016 to 2036. I am sure to say that system has

been designed with great care and all possible circumstances have considered.

Therefore I am very confident saying that system will be working very well throughout

its design period of 20 years which is from 2016 to 2036.

·

We used max diameter 530mm

for M1 to M158

·

We used min diameter 225mm.

·

Total No’s of manholes =

158

REFERENCES

References

- Water supply and sewerage by McGhee, 6th edition, McGraw Hill Inc.

- Class Lectures Notes.

- Design notes provided.

- WASA (1986) design criteria ,Water and Sanitation agency Lahore.

- Wikipedia, the free encyclopedia.

0 comments:

Post a Comment